quality of collapsing for impact tests|what is impact testing : mail order Quality Control: Regular impact testing during the production process ensures that materials and products meet specified standards and requirements. This helps maintain consistent quality and reduces the risk of defects that could compromise safety and performance. Siga Botola Pro 2023/2024 para placares ao vivo, resultados finais, calendário de partidas e tabelas de classificação! Placares ao vivo em Livesport.com: aqui você encontrará artilheiros, cartões amarelos/vermelhos, escalações e substituições nos detalhes da partida. E mais, Livesport.com fornece estatísticas (posse de bola, chutes .

{plog:ftitle_list}

Resultado da Mexico - Club Leones Negros de la Universidad de Guadalajara Premier - Results, fixtures, squad, statistics, photos, videos and news - Soccerway. Bahasa - Indonesia; Chinese (simplified) . Chihuahua FC 2 - 0 Leones Negros II 17/02/24: LPS: Leones Negros II 1 - 4 .

Quality Control: Regular impact testing during the production process ensures that materials and products meet specified standards and requirements. This helps maintain consistent quality and reduces the risk of defects that could compromise safety and performance.

qbd 1200 laboratory toc analyzer

Once the Charpy impact tester completes the test, the results are typically presented as the amount of energy absorbed during the fracture, measured in joules. These Charpy impact . Various studies have conducted the drop-weight impact test by releasing the drop-weight through guide rods or vertical tracks as shown in Fig. 1b. The use of guide rods may prevent this tilt of drop-weight, thereby .Impact testing is an important technique applied to assess the exact operational perform-ance of composites under physical collisions. The aerospace, automotive, marine, and other .

what is impact testing

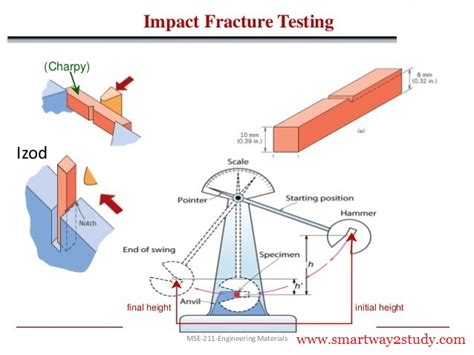

Abstract. This review provides an overview of experimental impact testing and numerical impact simulations for composite materials in terms of a complementary combination of both techniques. Charpy impact tests determine the strength and endurance of materials, their fracture rates, and their ability to absorb energy on impact.

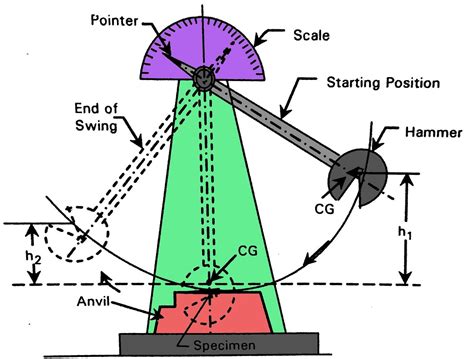

The scope of these impact test is to measure the answer of a standard test specimen to the pendulum-type impact load. The result is expressed in term of kinetic energy consumed by . An impact test is a technique used to determine a material’s ability to resist deformation when subjected to a sudden shock or impulse load. There are several different types of impact tests, but all entail striking a . Impact testing is a procedure that measures a material’s resistance to failure when subjected to high-rate loading. This method is used in multiple industries like automotive, aerospace, and construction to guarantee . This study provides a review of the contemporary understandings of the RC beam responses to impact loads, and explains the different observations and conclusions. Some unsolved issues for protective structures, .

types of impact testing

Charpy to ISO 179-1 is the preferred test method on plastics within the standard for single-point data ISO 10350-1. The test is ideally performed on unnotched specimens with edgewise impact (1eU). Should the specimen not break during the test, any subsequent tests are performed with notched specimens.

WHAT: Test resistance to penetration by sharp, solid objects; WHY: To test cardboard strength and sturdiness during transportation; Puncture resistance tests how well the box can handle the impact made with a pyramid or .

Based on four standard fire resistance tests that were conducted under a range of insulation and test conditions, NIST found the fire rating of the floor system to vary between 3/4hour and 2hours; in all cases, the floors continued to support the full design load without collapse for over 2 hours.

The recommendations have been written only for the whole channel, as this is the sole route by which subsystem performances affect the quality of the output. If it is difficult to measure the whole channel performance, which is usually the case, the test agency may treat the channel as two or more convenient subsystems. Based on the collapse modes and internal force transfer path, an innovative collapse-prevention design method (structural response-based design, or SRBD) is proposed. The SRBD method predicts the collapse response of structure at a theoretical level and avoids redundant modeling and nonlinear calculations in collapse-prevention design.The recommendations have been written only for the whole channel, as this is the sole route by which subsystem performances affect the quality of the output. If it is difficult to measure the whole channel performance, which is usually the case, the test agency may treat the channel as two or more convenient subsystems. impact to causing the collapse of . demonstrator flight testing”. Safety Science, 89 . The results show that the primary causes for the collapse are the poor construction quality, illegal .

A quarter of electric vehicles sold in the EU this year will be made in China, according to a new industry forecast, as the country’s new entrants continue to take sales from traditional .Tracheal collapse is a progressive disease of the trachea (windpipe) that causes chronic coughing. This is common in toy and small breed dogs such as Yorkshire Terriers, Pomeranians and Toy Poodles that are middle-aged or older. There is no cure for tracheal collapse, but ongoing medical management can improve clinical signs and quality of life.

Also, experimental dynamic tests are performed by use of a drop weight test machine.Achieving a good agreement of the results in previously mentioned analyses, follows to the design of impact .Impact testing is classified according to how a material resists impact. The following are the different types of impact test machines: Charpy Impact Test: The Chapy impact test is a widely used method to determine the toughness of a material. In this test, a pendulum is swung by a weight on the top of a test sample to create an impact.

All the passenger vehicles come with the crash protection bumper to absorb the impact force when a collision occurs during a road accident [1].The vehicle’s bumper is an essential part of the cars body which is designed to absorb impact energy and performs as protective case to most of the body parts of the vehicle such as bonnet, radiator grill, engine . General standards in the form of quality criteria can be used in order to assess the quality of an instrument and/or to construct a high-quality test. Three main indicators, the so-called “core quality criteria,” have emerged: objectivity, reliability and.to collapse for different reasons. With trains, it's the velocity of the impact that can bring a bridge down. With boats, it's the very large mass they have that can bring about the collapse, even if they are moving very slowly when it occurs. The best way to avoid bridge failures is to plan for them. Modern technologies that can detect

The chip impact test was originally developed in order to measuring the effect of surface microcracking caused . The Charpy impact test has gained the greatest importance in the quality control in the last years because of its easily applicability, short testing time and low consumption of materials during the test. But, on the other side, its

In nonsymmetrical members or structures, a resonant mode has a preferred direction of motion. Impact testing should be approached on an experimental basis by trying variations of impact velocity, direction, etc. Numerous frequencies may occur that make the mode shapes difficult to identify. Generally, the lower modes of vibration will be predominate.The main specifications requirements are the component drawing, artwork (printed components only) and the quality control testing and standards. Quality control testing and standards- There are two classes of components:-1. Primary – in contact with the product, e.g., ampules, vials, plastic bottles, polymer coated foils 2.An overview of mechanical and physical testing of composite materials. N. Saba, . M.T.H. Sultan, in Mechanical and Physical Testing of Biocomposites, Fibre-Reinforced Composites and Hybrid Composites, 2019 1.2.3 Impact test. The impact test is designed to determine how a specimen of a known material such as polymers, ceramics, and composites will respond to a .IMPACT TESTING MATTERS, NOW MORE THAN EVER 1.1 What is a Pendulum Impact Test An impact test determines a material’s resistance to an impact event. It measures the amount of energy the material absorbs when it is hit by a high-rate load. The most common impact test methods are Charpy and Izod and are typically run using a pendulum impact tester.

The impact testing machine is the apparatus used for this test. The test procedure is as follows. . Quality tests on stones are essential for ensuring their suitability in construction projects. Testing stone involves various tests, including crushing strength, water absorption, and abrasion resistance. Each test stone procedure is designed .

The recommendations have been written only for the whole channel, as this is the sole route by which subsystem performances affect the quality of the output. If it is difficult to measure the whole channel performance, which is usually the case, the test agency may treat the channel as two or more convenient subsystems. The test print is a total of 24mm high so I change settings every 8mm(3x) then compare the changes until I achieve the best result. The settings that will have the most impact are; flowrate, retraction distance/speed, coast, wipe, and extra restart distance. You may also try; seam location, speed, temperature, and z-hop. Key Standards for Sample Preparation and Impact Testing. ASTM E23: Standard Test Methods for Notched Bar Impact Testing of Metallic Materials. Scope: This standard specifies the requirements for notched-bar impact testing using both Charpy and Izod methods. It includes guidelines for specimen dimensions, preparation, and testing procedures.

Background: Excessive dynamic airway collapse (EDAC) represents pathologic obstruction, but the flow resistance it creates and the possible impact on pulmonary function tests is unclear. Our aims were to explore the flow resistance in a model, and in patients to relate observed EDAC to pulmonary function tests.Concrete slump test is carried out from batch to batch to check the uniform quality of concrete during construction. The slump test is the most simple workability test for concrete, involves low cost and provides immediate results. Due to this fact, it .Charpy Impact Testing isn’t just a routine quality control measure—it’s a critical tool for evaluating the resilience of materials in the face of sudden loads. When a sudden force strikes a material, can it withstand the impact without breaking or shattering into pieces? This is precisely what Charpy Impact Testing helps us understand.Two techniques currently are dominated for pile integrity testing, namely the Low Strain Method and the Cross-Hole Sonic Logging, both of them based on the sound waves interpretation (Amir et al. 2009). 2.1 Low Strain Method The low strain (sonic) method for the integrity testing of piles is aimed at routinely testing on piling sites.

Pompeii’s free slot machine, a no-download online pokie, allows instant browser play, ranking it among the top free online pokies. This format eliminates . Ver mais

quality of collapsing for impact tests|what is impact testing